News

CS2 Plant Project

Maurer is currently engineering and supplying a latest state of the art Carbon Disulfide Production plant in conjunction with an Acid Gas Treatment plant. The chosen process-technology yields highest efficiency at low investment cost whilst incorporating full...

Erection of a Spinning Line

Until the end of the year we are erecting a spinning line completely engineered and supplied by us. The plant will be able to produce high quality cellulosic fibres deemend for textile application. The process follows an eco-friendly design and incorporates latest...

Scale-Up of Cellulosic Aligner Discs for Medical Application

We have the opportunity to engineer the next scale of production together with our customer Bottmedical (Basel, Switzerland). Bottmedical has developed a unique production process for the manufacture of natural aligner discs, the base for a dentist to create ones...

New Plant Concept for Alternative Staple Fibre Stretching Rollers

We are currently executing Basic Engineering Work for a new plant concept. It combines an alternative process for the production of cellulosic staple fibre to be established on a brownfield site. This will allow for integration of several process steps and assure...

Stretching Rollers

Maurer has been challenged to redesign the Metall Stretching Rollers for one of its clients on several lines. The newly designed Rollers incorporate latest material developments and combine it with most suitable design. This saves weight and brings maintenance down...

Cellophane Casting Lips

We were able to deliver a set of brand new Cellophane Casting Lips. Made of special alloy guaranteeing highest corrosion resistance and durability of the material. This results in reduced maintenance efforts and leads to higher product quality. Maurer is crafting...

Revamping of Xanthat Machine

Two Maurer Xanthators with a batch size of 2’000 kg α-Cellulose each manufactured in 1980 are about to be completely revamped. The machines have been continuously in operation over the last 40 years and are still in such a good condition that revamping works are...

Laboratory Plant

Maurer is engineering, manufacturing and starting-up a complete laboratory plant for the production of regenerated cellulosic fibre, especially viscose. The laboratory plant is able to simulate the industrial process on a much smaller scale to suit laboratory...

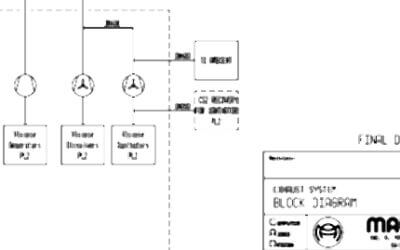

Basic Design for Exhaust System

Maurer is about to engineer a complete Basic Design for an Exhaust System. The capacity of this project is 600 tons per day of viscose staple fibre. Maurer is about to take care of: the complete design basis mass balances process flow diagrams piping and...

Automatic Spinneret Cleaning Machine

We currently commission and start up our new automatic spinneret cleaning machine at a customer in Indonesia. This machine has already proven as easier to operate, faster in cleaning cycles and a higher life span than others. Additional to these facts it also stands...

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information