Viscose Preparation

Viscose Preparation

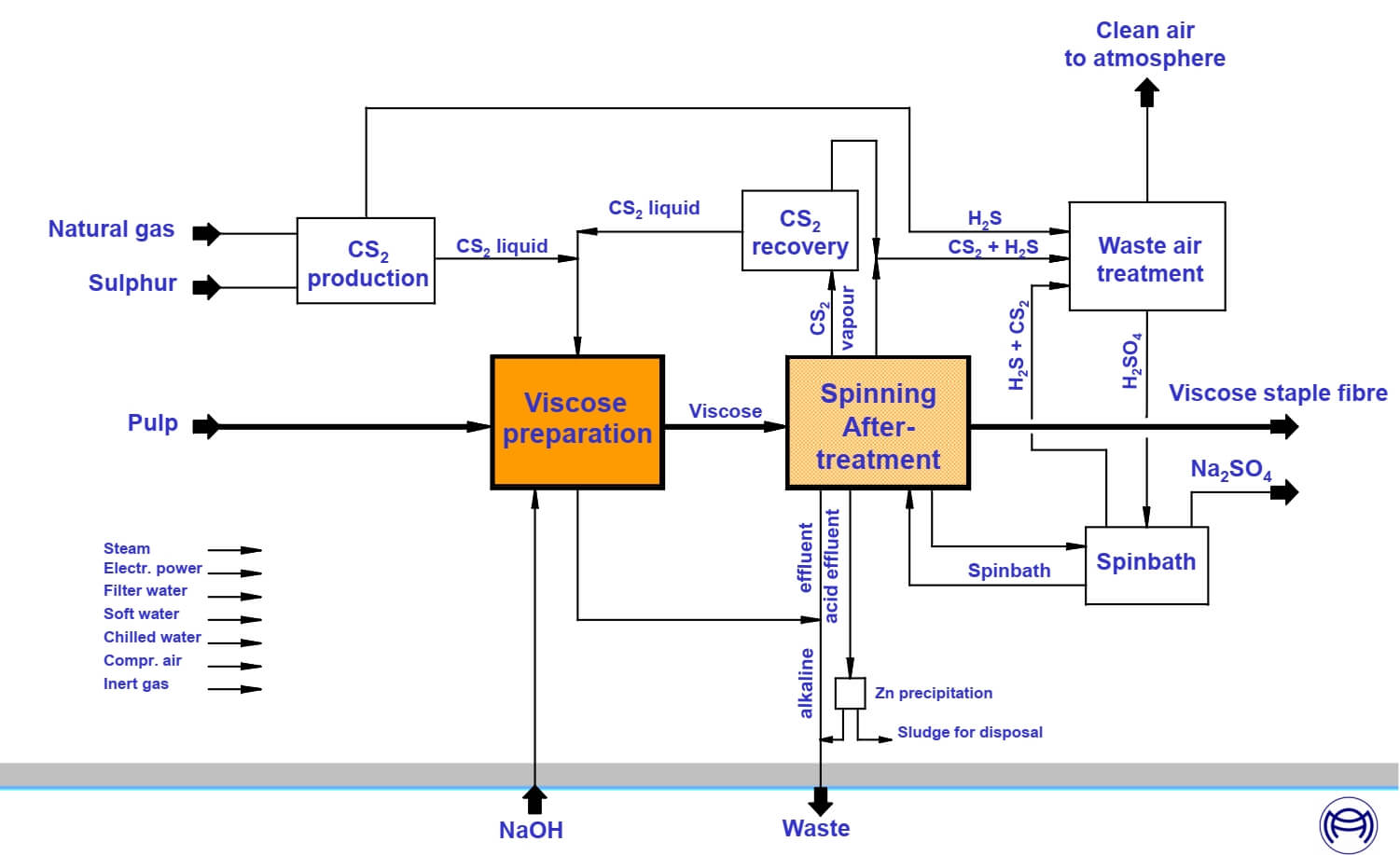

The process of preparation is crucial for every following process as it stands on top. Your end product will never be better than what You create here in preparation. The main steps in preparation are:

- Alkalising of the cellulose

- Ageing of the cellulose

- Xanthation (reaction caused by CS2)

- Disintegration of the A-cellulose -> leads to Viscose

- Homogenization, Filtration and Deaeration to reach a uniform viscose free of impurities and bubbles and ensure a trouble-free spinning solution.

We deliver completely harmonized preparation lines or single units adapted to suit Your individual needs.

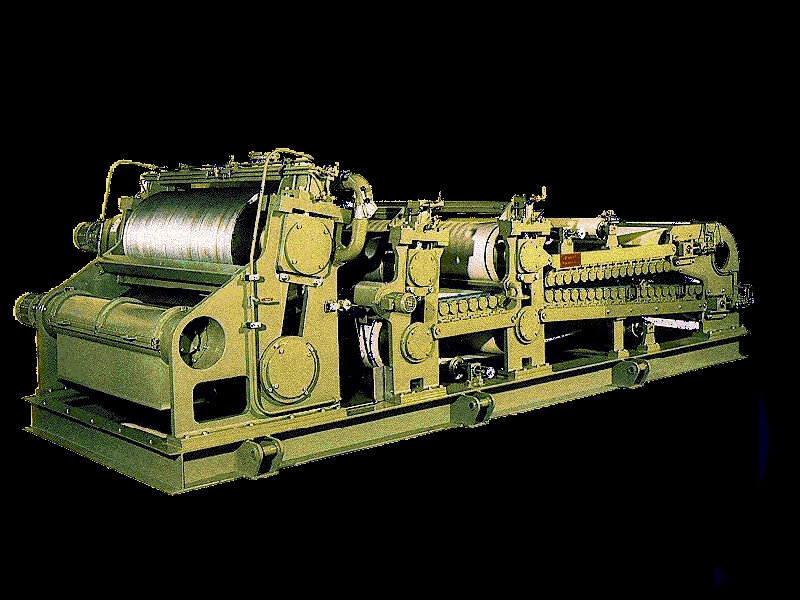

ALKALISATION

Standard design

- Slurry feed to fleece forming device without pressure

- First press part: Low pressure sieves

- Second press part: High pressure superimposed, grooved steel rolls

- Cutting of wet borders after first press part, no wet or thin fibre fleece

- Second lye addition for double steeping technology

- Speed control by frequency converters

- Sectional lye collection to separate lye with high hemicellulose content

Features

- Alkali cellulose (AC) obtained with uniform composition

- AC fleece thickness adjustment during operation by feed and speed control

- Universal with respect to pulp type processed

- Reduction of CS2 and NaOH input due to double steeping process in one single machine

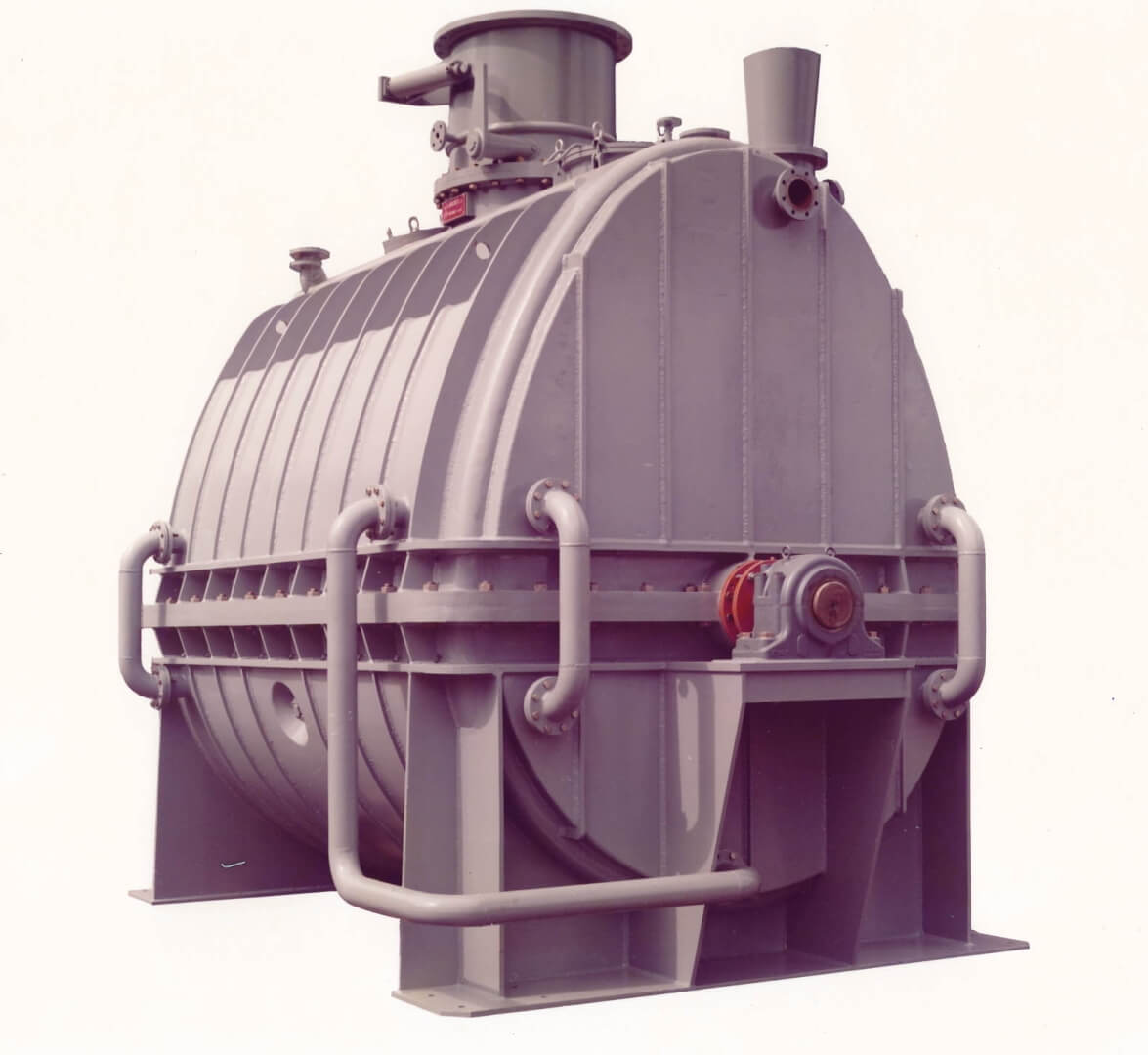

AGEING

Standard design

- Rotating drum

- Direct cooling with fresh cooled air

- Feed and discharge screw conveyors

- Inclined installation

- Closed system prevents AC losses

- Chain drive

Features

- Even depolymerisation to the required DP

- Effective cooling by direct contact

- AC can be stored in the ageing drum during short plant stop (buffer)

- No AC cooler required (done during pneumatic AC transport)

- Easy cleaning of the equipment when necessary

XANTHATOR

Standard design

- Wet churn with batchwise xanthation

- Oval Design (round design on request)

- Standard capacities from 660 to 3300 kg – cellulose / batch

- Special curved stirrer

- Electric or hydraulic drive with two speeds

- Fully automatic control, even stoppage of the reaction at xanthation process end

- Cleaning nozzles with dissolving lye jet

Features

- Equal quality in all batches

- No handling by the operator required during normal operation

- Safety precautions: vacuum control before every batch and inert gas blanketing

- No opening required due to efficent cleaning after every batch, no sticking

- Horizontal installation recommended (no inclination required)

- Handles all kinds of pulp

- Change of pulp does not cause problems or production loss

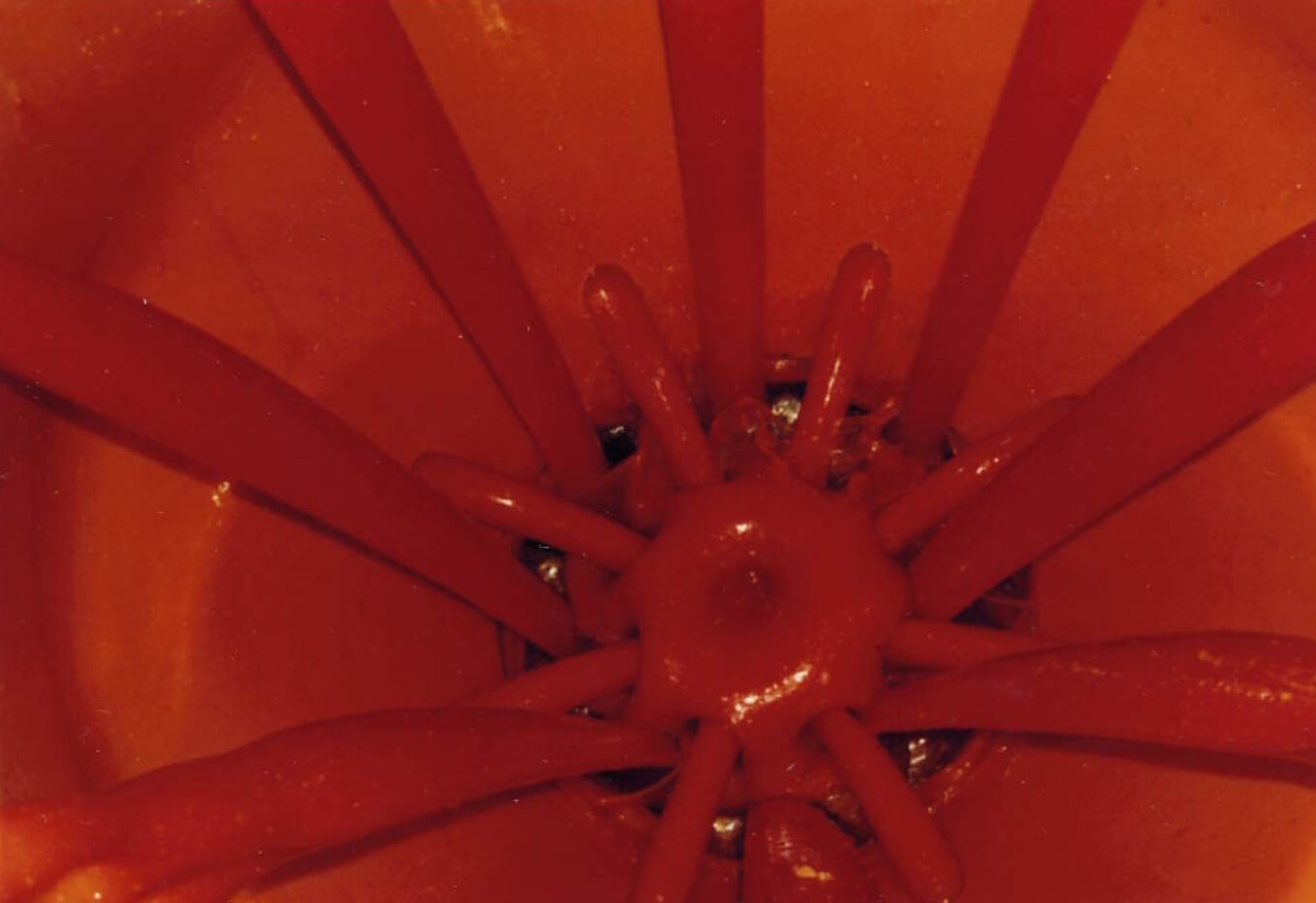

DISINTEGRATOR

Standard design

- Compact and simple

- Maintenance free design

- Each knife shaft separately driven

Features

- High production capacity

- Counter rotation of star-shaped knives to ensure optimal shear effect

- Different speed of rotating knife shafts

- Knifes can easily be exchanged

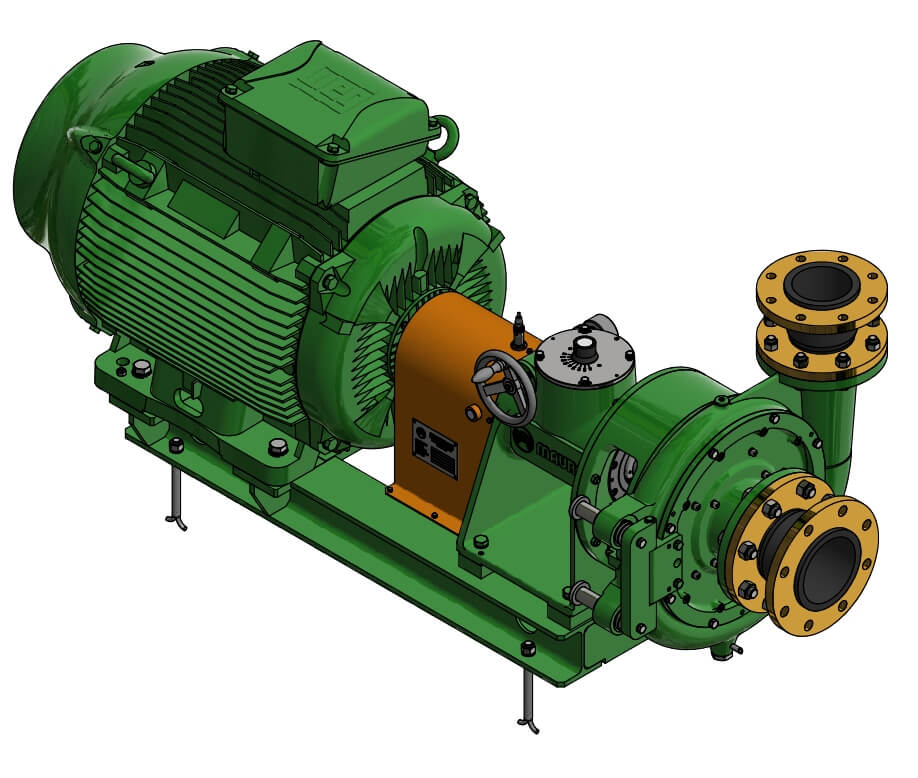

HOMOGENIZER

Standard design

- Operation principle: Stator/ rotor pair with several shear stages

- Shear stages in exchangeable ring form (different design available)

- Very fast dissolving/ homogenizing without circulation hence massive reduction in power consumption

- Manual adjustment of gap between stator and rotor, or by electrical servo motor while running (automatically adjustable for batch process or for viscosity variation in continuous system)

- For ease of inspection or cleaning the front end can be swung out

Features

- Industrially approved highest quality results in terms of viscosity and filterability

- Stator and rotor designed to develop a slight discharge pressure (for installation in closed circulation or feeding system)

- Casing, stator as well as rotor, especially designed in order to avoid dead spaces where viscose may coagulate and skins be formed

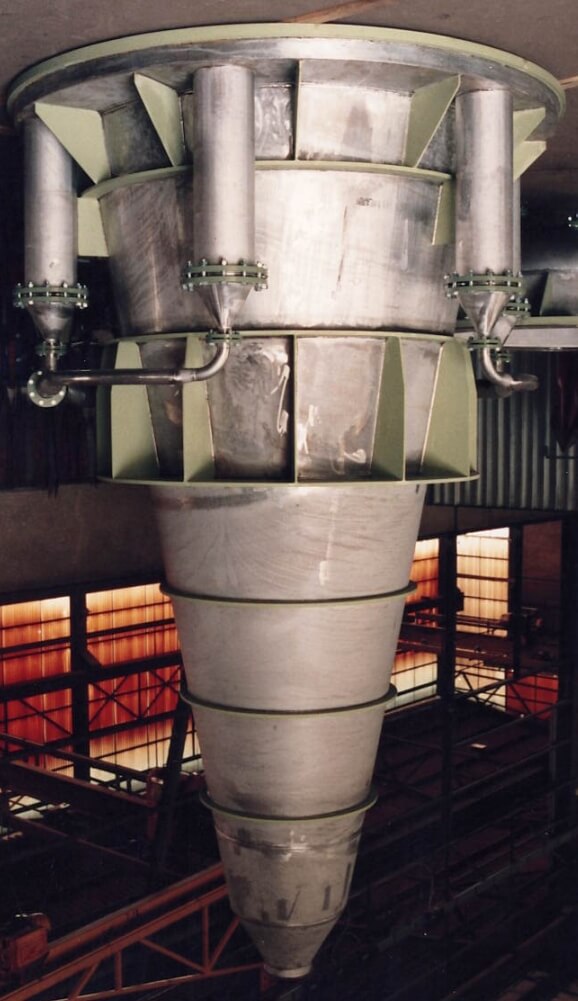

FLASH DEAERATOR

Standard design

- Vacuum deaerator with boiling viscose

- Feed through ring pipe and special feed nozzle

- Viscose distribution with overflow ring channel

- Tight system, tested by manufacturer

- Material of construction: stainless steel

Features

- High efficiency deaeration, no pre-deaerator required

- Even distribution of the viscose flow on the circumference

- No skin formation in the deaerator

Do you have questions about our products or technologies?

We will be happy to help you develop the right design for your individual needs.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information